NEWYou can now listen to Fox News articles!

Kansas City, MO – With Independence Day and the United States’ 250th anniversary just a year away, one Missouri company is stitching its way into history.

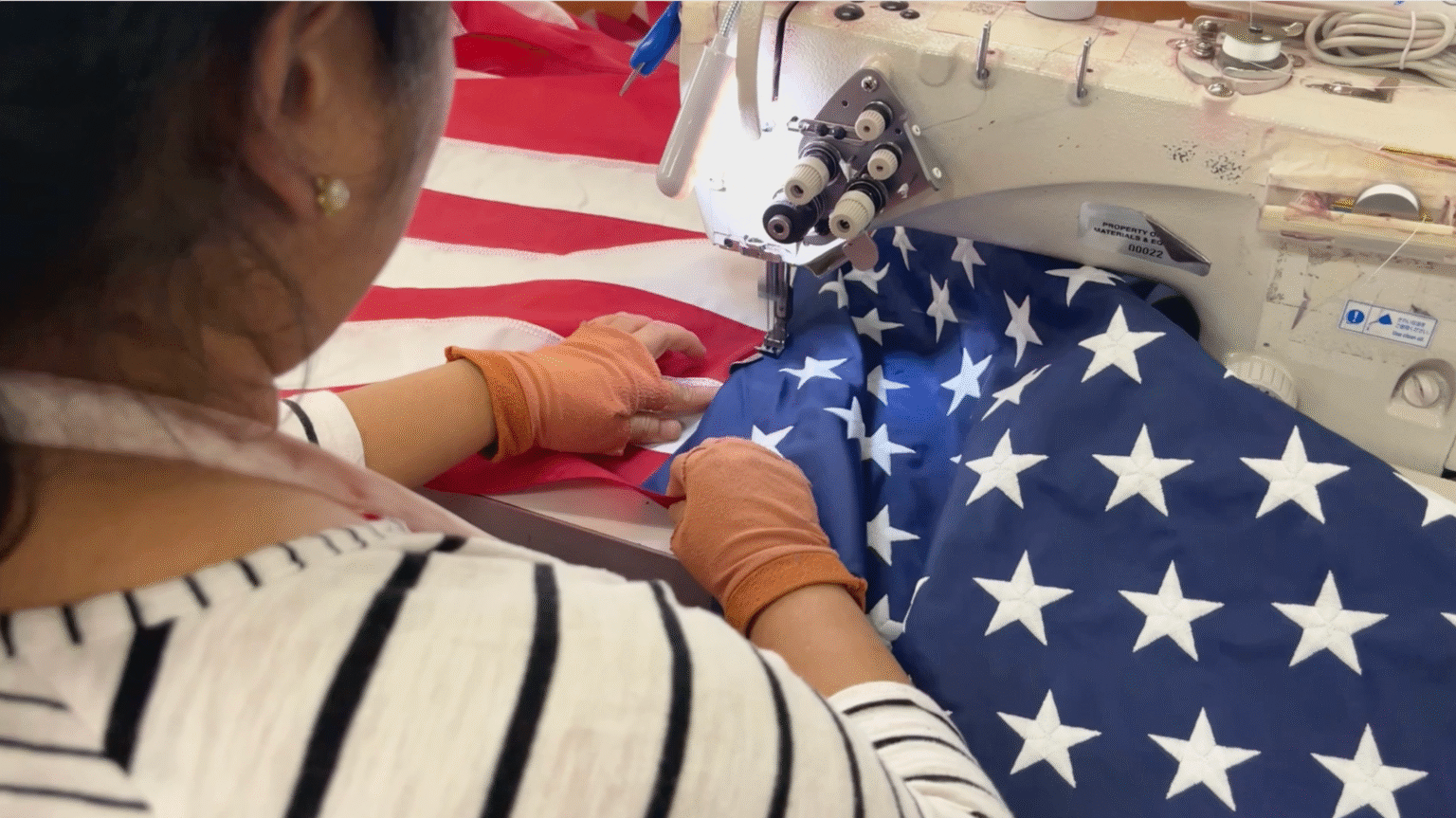

Allied Materials, based in Kansas City, has been manufacturing since 1951. The company now makes about 1,000 flags per day, with many destined for military funerals, government buildings and patriotic front porches nationwide.

“This is kind of our Christmas,” said Tyler Young, president of Allied Materials. “We start preparing months in advance, building extra inventory because we know this is the weekend Americans will show their patriotism most fervently.”

AMERICAN FLAGS FOR FAMILIES, FRIENDS AND NEIGHBORS ARE AT THE HEART OF THIS ENDEAVOR

The company is the largest vertically integrated flag manufacturer in the U.S., producing over 300,000 flags per year for federal agencies alone — including the U.S. Senate, the Department of Defense and military bases around the world.

“We make federal government-compliant flags,” Young said. “That means every single component is sourced in America — from the cotton seed to the dyed fabric. There are no corners cut, no costs spared. It truly is the best flag you can put in front of your home.”

TRUMP ANNOUNCES HE WILL KICK OFF INDEPENDENCE DAY WEEKEND WITH ‘VERY SPECIAL’ PATRIOTIC EVENT

Each flag begins with American-grown cotton or nylon, which is dyed, rolled and cut into stripes. Those are sewn together in Kansas City and joined with embroidered star fields made in the company’s Louisiana facility. All flags are inspected and trimmed before the final touch: metal grommets that make them ready to fly.

“From start to finish, that flag may only take a couple hours,” Young said. “But the purpose it serves lasts a lifetime.”

For many of Allied’s employees, that purpose is personal.

DISABLED VETERAN FIGHTS HOMEOWNERS ASSOCIATION LAWSUIT OVER FLAGPOLE IN FLORIDA YARD

“These people work really hard,” said longtime machine technician Terry Walker. “Every fallen veteran gets one of these flags. And it’s an honor to work here.”

Young said that seriousness is shared company-wide. “The next time someone sees this flag, it may be draped over a veteran’s coffin. It needs to be perfect. We owe it to that soldier and their family to honor their sacrifice.”

As the U.S. looks ahead to its semiquincentennial in 2026, Allied is preparing for what could be the largest flag-flying event in American history.

PLAN AN EPIC INDEPENDENCE DAY MOVIE MARATHON WITH THESE TVS AND PROJECTORS

“We’re starting our marketing plan now and building inventory this fall,” Young said. “We want to be ready for everyone — whether they’re a homeowner looking to fly a flag or a government agency planning a ceremony. We’ll be here.”

According to STG Logistics, roughly 94% of American flags sold in the U.S. are made domestically — a point of pride for Young, especially as recent tariffs on imports disrupted global supply chains.

MAKE SURE YOUR KIDS HAVE FUN ON INDEPENDENCE DAY WITH THESE FOURTH OF JULY ESSENTIALS

“When other suppliers were hit by tariffs, we weren’t,” he said. “It was actually kind of fun to call our customers and say, ‘Today you’re getting a call from an American manufacturer who makes American-made products with American raw materials.’”

Allied’s flags range in size from two feet by three feet up to ten by fifteen, and each one meets federal standards for stitching, star size and durability — whether it’s headed to a front yard or the steps of the Capitol.

“A flag isn’t just a product,” Young said. “It’s a symbol of our nation’s history — and of everyone who’s been part of the fabric of this country.”

All images and information were captured during a site visit to Allied Materials, a flag manufacturing facility based in Kansas City, Missouri.

Read the full article here